Some Expert Advice…

My expertise with these cars is at your service. I have probably encountered just the problem that is driving you crazy. Give me a call ( 9 am – 9pm PST) and we will discuss it over the phone. As always, tech advice is FREE (up to a certain point).

When working on these cars you MUST have the technical manuals and service books. They are available from this website or the parts suppliers listed in the ‘Recommended Vendors“‘ link here.

BLEEDING THE TOP / DECK HYDRAULIC SYSTEM: 1961-1965

Install all top cylinders & lines, leaving pump motor unit dismounted and sitting UP RIGHT with filler plug removed. In this position, it is easier to fill, and won’t suck air (zip-tie is helpful)

Hydraulic rams are to remain disconnected from deck lid & convertible top (where ram attaches) Don’t forget a prop rod to keep deck lid from falling! It is also good idea to place a support (rag or paper towel roll) under the top cylinders to hold them up; so when ram moves in & out, it does not hit anything.

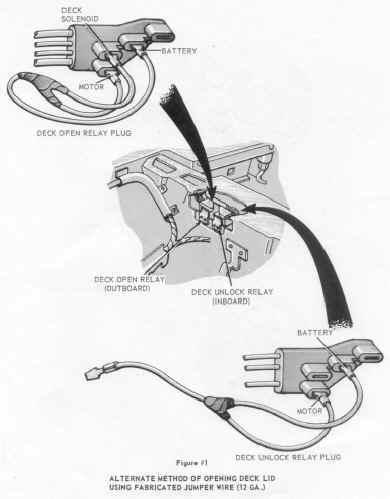

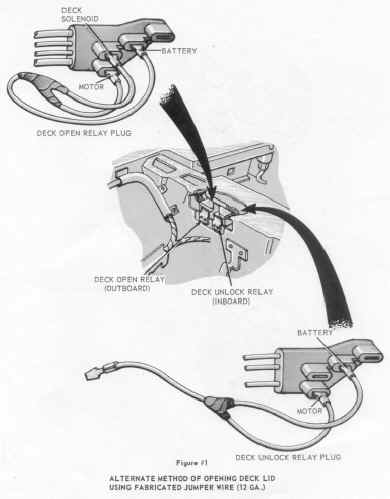

A completely empty system will hold approximately 3 1/2 quarts of transmission fluid (use type F) You will need a 3 way jumper wire with alligator clips (12-14 gauge) For power, use circuit breaker located just above pump ( it is always powered)

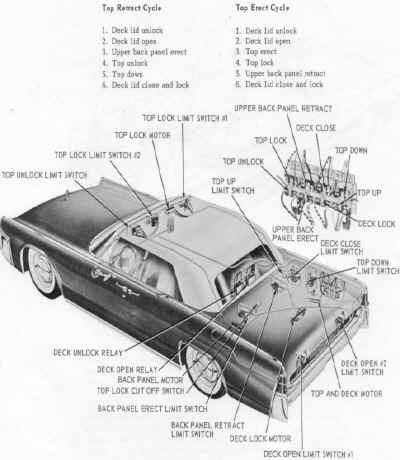

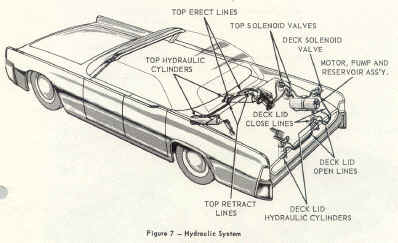

You are going to be “shooting blanks” Before hot-wiring the pump, you must open the appropriate solenoid valve. The valve closest to tail light is for the DECK cylinders. The two values closest to the tire are for the TOP cylinders. When bleeding the top system, you must energize BOTH top valves simultaneously. Solenoid valves have one black wire going into a bullet connector: disconnect that bullet connector to energize.

Alternate bleeding deck & top system: jump power to deck solenoid valve ( you will hear it click) Then energize either yellow wire or red wire on pump. when rams get either all the way in or all the way out, immediately cut power to pump… then go the other direction. Try to anticipate when the ram is out / in, to avoid over pressurizing (which is easy to do)

Add fluid to reservoir, but NEVER fill more than 80% full. Any air in the system will end up in this reservoir, and vent. Leave filler plug out thru entire procedure.

After running deck rams in /out for several cycles, “shoot blanks” on the top cylinders. Remember to energize BOTH solenoid valves closest to tire; then energize either yellow or red wire on the pump motor unit. If cylinders are new and empty, you will have to fill reservoir about 3 times before rams move.

Do not energize solenoid valves more than 3-5 minutes, without a rest to cool down. Also, if pump is too hot to touch, it should be allowed to cool, as well. Having a battery charger on the battery will insure good power, as this procedure draws approximately 30-40 amps.

After alternating bleeding top and deck systems, and cylinders are working evenly; hot wire rams to appropriate positions, install pins and mount pump. Correct level of fluid in reservoir when mounted, is 1 inch down from filler plug, at 12 o’clock position (top)

1961 -1967 PRODUCTION FIGURES

LINCOLN CONVERTIBLES & HARDTOPS:

1961 Lincoln 4d Convertible: 2,857

1961 Lincoln 4d Sedan: 22,303

1962 Lincoln 4d Convertible: 3,212

1962 Lincoln 4d Sedan: 27.849

1963 Lincoln 4d Convertible: 3,138

1963 Lincoln 4d Sedan: 28,095

1964 Lincoln 4d Convertible: 3,328

1964 Lincoln 4d Sedan: 32,969

1965 Lincoln 4d Convertible: 3,356

1965 Lincoln 4d Sedan: 36,824

1966 Lincoln 4d Convertible: 3,180

1966 Lincoln 4d Sedan: 35,809

1966 Lincoln 2d Coupe: 15,766

1967 Lincoln 4d Convertible: 2,276

1967 Lincoln 4d Sedan: 32,331

1967 Lincoln 2d Coupe: 11,060

TOTAL CONVERTIBLES: 21,347

TOTAL SEDANS: 216,180

TOTAL COUPES: 26,796

Emergency Convertible Deck Lid Opening Procedure